Maintaining your Samsung 130 excavator parts is essential to ensure their longevity and optimal performance. Regular preventive maintenance not only helps you extend equipment life span but also enhances the efficiency of your excavator. By taking proactive steps, you can avoid costly repairs and enjoy a longer machine life span. Preventive maintenance reduces downtime, improves operations, and ensures fewer repair costs. A well-maintained excavator operates more reliably, allowing you to achieve better productivity and efficiency in your projects.

Key Takeaways

Regular cleaning of your excavator prevents dirt buildup, which can lead to premature wear and operational inefficiencies.

Proper lubrication of moving parts is essential to reduce friction and extend the lifespan of your excavator components.

Investing in operator training helps prevent misuse, reducing wear and tear on critical parts and improving overall machine performance.

Avoid overworking your excavator by adhering to load limits and taking regular breaks to prevent mechanical failures.

Establishing a consistent maintenance schedule allows for early detection of issues, reducing downtime and costly repairs.

Regular Cleaning to Prevent Dirt Buildup

Keeping your Samsung 130 excavator clean is one of the most effective maintenance practices to ensure its longevity and performance. Dirt, debris, and grime can accumulate on critical components, leading to premature wear and operational inefficiencies. Regular cleaning not only helps maintain the appearance of your equipment but also plays a vital role in preserving its functionality.

Why Cleaning is Essential for Samsung 130 Excavator Parts

Dirt buildup can cause significant damage to your excavator over time. When debris collects around moving parts like the bucket pivot points, it increases friction and accelerates wear. This can lead to costly repairs or replacements. Additionally, dirt and grime can trap moisture, which promotes rust and corrosion on metal surfaces. Corrosion weakens the structural integrity of parts, reducing their lifespan.

By keeping your equipment clean, you prevent these issues and ensure smooth operation. Clean equipment also allows you to spot potential problems, such as cracks or leaks, during routine inspections. This proactive approach helps you address minor issues before they escalate into major repairs.

Best Practices for Cleaning Excavators

To effectively clean your excavator, follow these best practices:

Tools and Techniques for Cleaning Critical Components

Use High-Pressure Washers

A high-pressure washer is ideal for removing stubborn dirt and grime from the excavator’s surface. Focus on areas like the bucket, boom, and arm, where debris tends to accumulate. Avoid directing high-pressure water at sensitive components like electrical connections or hydraulic seals.Brushes and Scrapers for Hard-to-Reach Areas

Use brushes and scrapers to clean areas that are difficult to access, such as the bucket teeth and pivot points. These tools help remove compacted dirt without damaging the parts.Degreasers for Oily Residue

Apply a degreaser to areas with oil or grease buildup, such as the engine compartment and hydraulic system. Let the degreaser sit for a few minutes before rinsing it off with water.Dry the Equipment Thoroughly

After washing, dry the excavator completely to prevent moisture from causing rust. Use a clean cloth or air compressor to remove water from crevices and joints.Inspect and Maintain Buckets Post-Cleaning

Once the bucket is clean, inspect it for signs of wear, such as cracks or loose bolts. Tighten any loose fasteners and replace damaged parts to ensure the bucket operates efficiently.

Regular cleaning not only enhances the performance of your excavator but also extends the lifespan of its components. By incorporating these maintenance practices into your routine, you can keep your equipment in top shape and avoid unnecessary downtime.

Proper Lubrication of Moving Parts

Lubricating the moving parts of your Samsung 130 excavator is a critical step in maintaining its performance and durability. Without regular parts lubrication, friction increases between components, leading to wear and tear that can shorten the lifespan of your equipment. Proper lubrication ensures smooth operation, reduces the risk of premature failure, and keeps your excavator running efficiently.

Importance of Lubrication in Excavator Maintenance

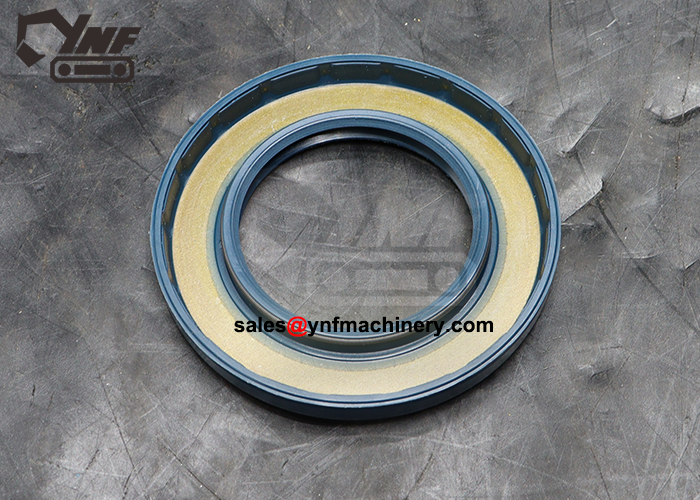

Lubrication plays a vital role in protecting the moving parts of your excavator. Components like pivot points, couplings, and hydraulic systems experience constant motion and pressure during operation. This movement generates heat and friction, which can cause parts to degrade over time. A properly lubricated equipment minimizes these effects, ensuring that parts move seamlessly without unnecessary strain.

When you apply lubrication regularly, you create a protective barrier that reduces metal-to-metal contact. This barrier prevents corrosion, dissipates heat, and enhances the overall efficiency of your excavator. Neglecting this essential maintenance task can lead to costly repairs and unexpected downtime, which disrupts your projects and increases expenses.

How to Lubricate Effectively

To maximize the benefits of lubrication, you need to follow a systematic approach. Proper application and the use of high-quality lubricants are key to keeping your excavator in top condition.

Using High-Quality Lubricants for Components Like Excavator Couplings and Pivot Points

Choose the Right Lubricant

Select a lubricant that matches the specifications of your excavator. High-quality lubricants designed for heavy machinery provide better protection and last longer under extreme conditions. For components like excavator couplings and pivot points, ensure the lubricant can handle high pressure and resist water washout.Follow a Regular Schedule

Establish a routine for lubrication based on the manufacturer’s recommendations. Regular parts lubrication, such as greasing pivot points every 8 hours of operation, prevents wear and keeps the machine running smoothly.Clean Before Applying Lubricant

Always clean the parts before applying lubricant. Dirt and debris can mix with grease, creating an abrasive paste that accelerates wear. Use a clean cloth or brush to remove contaminants from the surface.Apply Lubricant Evenly

Use a grease gun or applicator to distribute the lubricant evenly across the surface. Focus on areas with high movement, such as the boom, arm, and bucket pivot points. Avoid over-lubricating, as excess grease can attract dirt and cause buildup.Inspect While Lubricating

Take the opportunity to inspect parts for signs of damage, such as cracks or unusual wear. Early detection of issues allows you to address them before they escalate into major problems.

By incorporating proper lubrication into your maintenance routine, you can extend the life of your excavator and improve its reliability. YNF Machinery offers high-quality lubricants and replacement parts, ensuring your equipment remains in peak condition. Trust YNF Machinery as your go-to supplier for all your excavator maintenance needs.

Operator Training to Avoid Misuse

Proper training for excavator operators is essential for extending excavator part life and ensuring efficient operation. Skilled operators not only handle the equipment with precision but also help prevent unnecessary wear and tear on critical components. By investing in operator training, you can significantly reduce maintenance costs and improve the overall performance of your machine.

The Role of Skilled Operators in Extending Equipment Life Span

Operators play a crucial role in extending the lifespan of your excavator. Their understanding of the equipment’s capabilities and limitations directly impacts its upkeep. When operators misuse the machine, such as overloading the bucket or applying excessive force during digging, it accelerates wear on parts like hydraulic systems, couplings, and pivot points. Skilled operators, on the other hand, know how to balance efficiency with care, ensuring that the excavator performs optimally without unnecessary strain.

“Providing ongoing training to operators helps them understand the equipment’s limitations and efficiently handle different construction tasks.”

Training also equips operators to recognize early signs of potential issues. For example, they can identify unusual noises, reduced hydraulic performance, or visible wear on components like the bucket teeth or hydraulic cylinder seals. Early detection allows you to address problems before they escalate, saving time and money on repairs.

Training Tips for Proper Excavator Operation

To ensure your operators are well-prepared, focus on these key training areas:

Identifying Early Signs of Wear in Parts Like Hydraulic Cylinder Seal Kits

Teach Operators to Perform Daily Inspections

Encourage operators to inspect the excavator before and after each use. They should check for visible signs of wear, such as cracks in the bucket, leaks in hydraulic lines, or loose bolts. Paying attention to hydraulic cylinder seal kits is especially important, as leaks can compromise the machine’s performance.Emphasize Proper Bucket Usage

Train operators to avoid overloading the bucket or using it for tasks it wasn’t designed for, such as prying heavy objects. Overloading puts excessive stress on the boom, arm, and pivot points, reducing their lifespan. Proper bucket handling ensures smoother operation and extends the life of these components.Highlight the Importance of Smooth Movements

Abrupt or jerky movements can strain the excavator’s parts, leading to premature wear. Teach operators to use smooth, controlled motions when operating the boom, arm, and bucket. This approach minimizes stress on hydraulic systems and mechanical joints.Provide Guidance on Load Limits

Operators should understand the machine’s load capacity and avoid exceeding it. Overloading not only damages the bucket but also affects the engine and hydraulic systems. Clear guidelines on load limits help maintain the excavator’s structural integrity.Train on Recognizing Hydraulic Issues

Hydraulic systems are vital for excavator operation. Teach operators to identify signs of hydraulic problems, such as slow response times, unusual noises, or visible leaks. Early intervention can prevent costly repairs and extend the life of hydraulic components.

By implementing these training practices, you empower your operators to use the excavator responsibly and efficiently. Skilled operators contribute to extending excavator part life, reducing downtime, and improving overall productivity. For high-quality replacement parts and expert support, trust YNF Machinery as your preferred supplier. YNF Machinery offers durable components, such as hydraulic cylinder seal kits and buckets, to keep your equipment running smoothly.

Avoiding Overworking the Excavator

Overworking your Samsung 130 excavator can lead to significant mechanical issues and costly downtime. Understanding the risks and adopting preventive measures will help you maintain the efficiency and longevity of your equipment.

Risks of Overworking Samsung 130 Excavator Parts

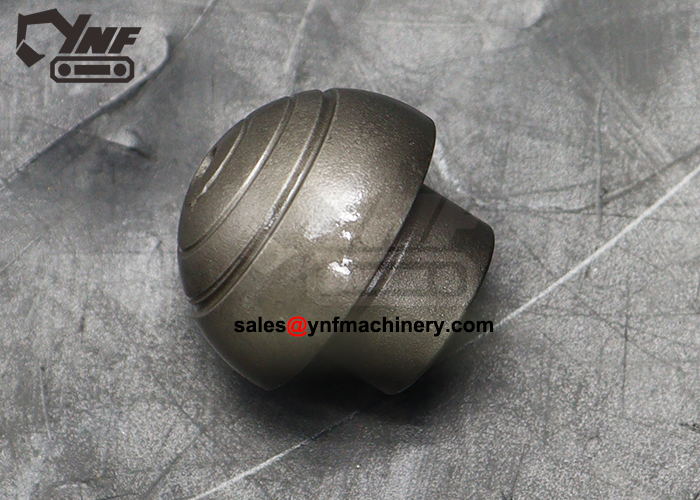

Pushing your excavator beyond its limits can result in severe consequences. Overloading the bucket or operating the machine for extended periods without breaks increases stress on critical components. This excessive strain can cause mechanical failures, such as damaged hydraulic pumps or worn-out pivot points. Over pressurizing the hydraulic system, for instance, may lead to premature wear or even complete failure of the pump.

When the excavator operates under constant pressure, heat builds up in the hydraulic system. This heat accelerates wear on seals and hoses, leading to leaks and reduced performance. Over time, these issues can escalate, requiring expensive repairs and causing prolonged downtime. By recognizing these risks, you can take steps to prevent overworking and protect your investment.

How to Prevent Overworking

Preventing overworking involves adopting smart operational practices and monitoring the excavator’s workload. These steps will help you avoid unnecessary strain on your equipment.

Monitoring Load Limits and Taking Breaks During Extended Use

Adhere to Load Capacity Guidelines

Always operate the excavator within its specified load limits. Overloading the bucket not only damages the boom and arm but also affects the engine and hydraulic systems. Refer to the manufacturer’s guidelines to ensure you stay within safe operating parameters.Distribute Workloads Evenly

Avoid concentrating heavy tasks in a single session. Spread out demanding operations over time to reduce continuous stress on the excavator. This approach helps maintain consistent performance and prevents overheating.Take Regular Breaks

Allow the excavator to cool down during extended use. Frequent breaks reduce heat buildup in the hydraulic system and prevent wear on moving parts. Use this downtime to inspect the bucket, hoses, and other components for signs of wear or damage.Monitor Hydraulic System Performance

Keep an eye on the hydraulic system’s pressure and temperature levels. Unusual readings may indicate overworking or potential issues. Address these signs promptly to avoid further damage.Train Operators on Proper Usage

Ensure operators understand the importance of avoiding overworking. Provide training on load management and efficient operation techniques. Skilled operators can identify early signs of strain, such as unusual noises or reduced responsiveness, and take corrective action.

By implementing these practices, you can prevent overworking and extend the life of your Samsung 130 excavator. Regular maintenance and responsible operation are key to avoiding costly repairs and downtime. For high-quality replacement parts and expert support, trust YNF Machinery as your preferred supplier. YNF Machinery offers durable components, including buckets and hydraulic parts, to keep your excavator running smoothly.

Establishing a Consistent Maintenance Schedule

A consistent maintenance schedule is essential for keeping your Samsung 130 excavator in peak condition. By adhering to a structured plan, you can prevent unexpected breakdowns, reduce costly repairs, and extend the lifespan of your equipment. Regular maintenance ensures that your excavator operates efficiently, allowing you to complete projects on time without interruptions.

Benefits of Routine Maintenance for Excavators

Routine maintenance offers numerous advantages for your excavator. It helps you identify and address minor issues before they escalate into major problems. For example, visual inspections during scheduled routine maintenance can reveal early signs of wear, such as cracks in components or loose bolts. Addressing these issues promptly reduces the risk of equipment failure and downtime.

Preventive maintenance also enhances the safety of your operations. A well-maintained excavator performs reliably, minimizing the chances of accidents caused by mechanical failures. Additionally, regular maintenance improves the overall efficiency of your machine. Clean and lubricated parts work seamlessly, reducing fuel consumption and ensuring smooth operation.

“Sticking to an excavator maintenance schedule can help you minimize downtime and keep your machine working when you need it.” – Cat Used

By committing to a daily maintenance routine and scheduled inspections, you can save money on repairs and maximize the productivity of your excavator.

Creating a Maintenance Plan

Developing a maintenance schedule tailored to your excavator’s needs is crucial for long-term performance. A comprehensive maintenance plan should include regular inspections, lubrication, cleaning, and part replacements. Following a structured plan ensures that no aspect of your excavator’s upkeep is overlooked.

Incorporating Regular Inspections of Excavator Engine Parts and Other Critical Components

Perform Visual Inspections Daily

Begin each day with a thorough visual inspection of your excavator. Check for leaks, cracks, or unusual wear on critical components like the engine, hydraulic hoses, and pivot points. Pay close attention to excavator engine parts, as they are vital for powering your machine.Schedule Preventive Maintenance Tasks

Include tasks such as oil changes, filter replacements, and lubrication in your maintenance plan. Preventive maintenance reduces the risk of equipment failure and ensures optimal performance. For example, changing the engine oil and filters monthly keeps the engine running smoothly.Inspect Hydraulic Systems Regularly

Monitor the hydraulic system for signs of wear or leaks. Regular inspections help you detect potential issues early, preventing costly repairs. Replace worn-out seals and hoses promptly to maintain system efficiency.Clean and Maintain Key Components

Keep the excavator clean to prevent dirt buildup, which can cause premature wear. Focus on areas like the bucket, boom, and arm. Cleaning these parts regularly ensures smooth operation and extends their lifespan.Track Maintenance Activities

Maintain a log of all maintenance tasks performed on your excavator. This record helps you track when specific components were last inspected or replaced, ensuring you stay on top of your maintenance schedule.

By following these steps, you can develop a maintenance schedule that keeps your excavator in excellent condition. Regular maintenance not only reduces downtime but also enhances the safety and efficiency of your operations. For high-quality replacement parts and expert support, trust YNF Machinery as your preferred supplier. YNF Machinery offers durable components, including excavator engine parts, to help you maintain your equipment effectively.

By following these five maintenance tips, you can keep your Samsung 130 excavator in excellent condition. Regular cleaning, proper lubrication, operator training, avoiding overworking, and establishing a consistent maintenance schedule all play vital roles in extending the life of your equipment. Proactive maintenance not only prevents costly repairs but also ensures your excavator operates efficiently, reducing downtime and enhancing productivity. Start implementing these tips today to protect your investment. For high-quality excavator parts and reliable support, choose YNF Machinery as your trusted supplier.

FAQ

What is the importance of proper excavator maintenance?

Proper maintenance ensures your excavator operates efficiently and lasts longer. Regular upkeep helps you identify minor issues early, preventing them from escalating into major problems. This reduces the risk of unexpected breakdowns and costly repairs. Maintenance also enhances productivity by minimizing downtime and ensuring smooth operation on construction sites.

Pro Tip: A well-maintained excavator not only saves money but also improves safety and reliability during operations.

What are some common maintenance issues with excavators?

Excavators often face several maintenance challenges. Common issues include hydraulic system leaks, electrical malfunctions, engine performance problems, and wear on components like the undercarriage. Tracks and rollers in the undercarriage are particularly prone to damage due to constant contact with rough terrain. Addressing these issues promptly can prevent further damage and ensure consistent performance.

How can I extend the life of my excavator’s undercarriage?

To extend the life of your excavator’s undercarriage, follow these tips:

Inspect Daily: Check for wear, cracks, or loose bolts in the tracks and rollers.

Clean Regularly: Remove dirt and debris to prevent buildup that accelerates wear.

Adjust Track Tension: Maintain proper tension to avoid unnecessary strain on the undercarriage.

Operate on Suitable Terrain: Avoid rocky or uneven surfaces when possible to reduce stress on components.

By taking these steps, you can significantly increase the lifespan of your undercarriage and reduce repair costs.

What are the benefits of using genuine Samsung 130 excavator parts?

Genuine Samsung 130 excavator parts are designed for precision and durability. These parts ensure optimal performance, reliability, and longevity for your equipment. Using authentic components minimizes the risk of compatibility issues and enhances the overall efficiency of your excavator. Genuine parts also reduce the frequency of repairs, saving you time and money in the long run.

How often should I inspect the undercarriage of my excavator?

You should inspect the undercarriage daily. Regular inspections help you identify signs of wear, such as loose bolts, damaged tracks, or worn rollers. Early detection allows you to address these issues before they lead to costly repairs or downtime. Consistent monitoring ensures your excavator remains in top condition.

What steps can I take to prevent undercarriage damage?

Preventing undercarriage damage involves adopting smart operational practices:

Avoid Overloading: Excessive weight can strain the tracks and rollers.

Use Proper Techniques: Operate the excavator smoothly to minimize stress on the undercarriage.

Monitor Terrain: Avoid sharp turns or operating on rocky surfaces whenever possible.

Clean After Use: Remove mud and debris to prevent accelerated wear.

These measures help maintain the integrity of your undercarriage and extend its lifespan.

Why is cleaning the undercarriage essential?

Cleaning the undercarriage is crucial because dirt and debris can cause premature wear. Mud and rocks trapped in the tracks or rollers increase friction, leading to faster deterioration. Regular cleaning prevents buildup, reduces strain on components, and ensures smooth operation. A clean undercarriage also makes it easier to spot potential issues during inspections.

How do I know when to replace undercarriage components?

Replace undercarriage components when you notice significant wear or damage. Signs include:

Cracks or breaks in the tracks.

Excessive wear on rollers or sprockets.

Difficulty maintaining track tension.

Reduced performance or unusual noises during operation.

Timely replacement prevents further damage and ensures your excavator continues to operate efficiently.

Can YNF Machinery help with undercarriage maintenance?

Yes, YNF Machinery offers high-quality replacement parts for your excavator’s undercarriage. From tracks to rollers, their durable components ensure reliable performance and longevity. YNF Machinery also provides expert support to help you maintain your equipment effectively. Trust YNF Machinery as your go-to supplier for all your excavator maintenance needs.